“Regarding the issue with solid waste, plastic bottles can be reused and turned into prosthesis for people with low economic resources, causing a strong impact on society.”

Do you know how do those people obtain prostheses?

People with low economic resources do not even think of having a prosthesis. According to our research, there are products that harm disabled people instead of helping them. Fixed prosthesis, for example, can damage the spine. That is why we put emphasis in developing a good design.

As your mother is a professional in health, you had to prove the viability of your proposal to her.

When I told her the material we were going to use, she only said, “Plastic?”. She was surprised, as she did not know that material can be useful in many ways, even alloys are possible. For instance, the PET plastic ―which is used for bottles, is highly resistant and does not corrode― can be mixed with other types of plastics to add new properties.

How many bottles are needed for one prosthesis?

Around 300.

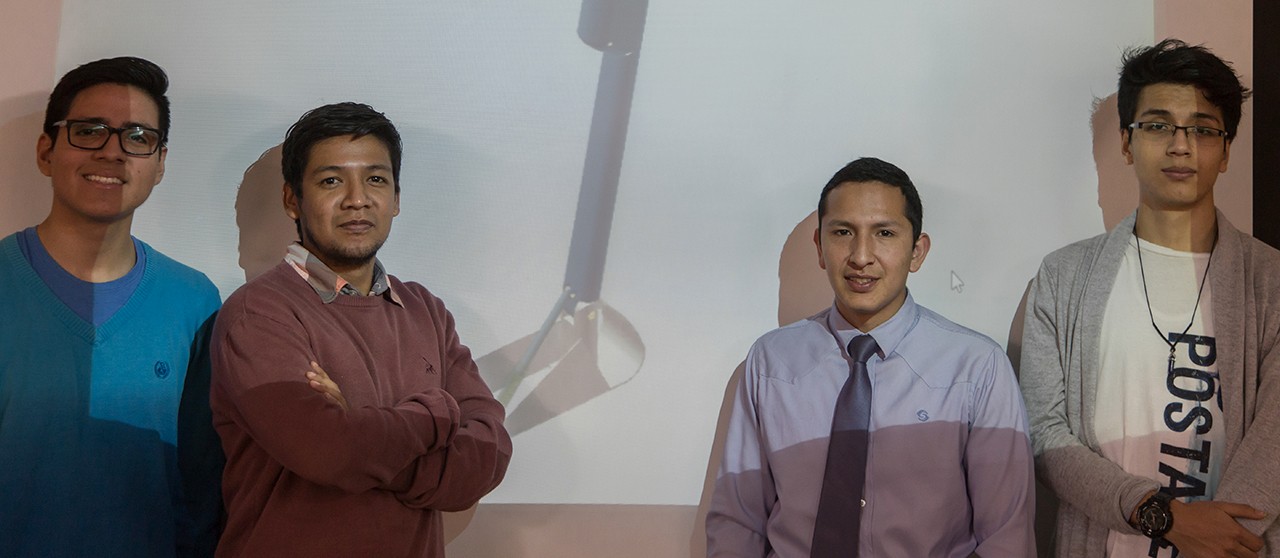

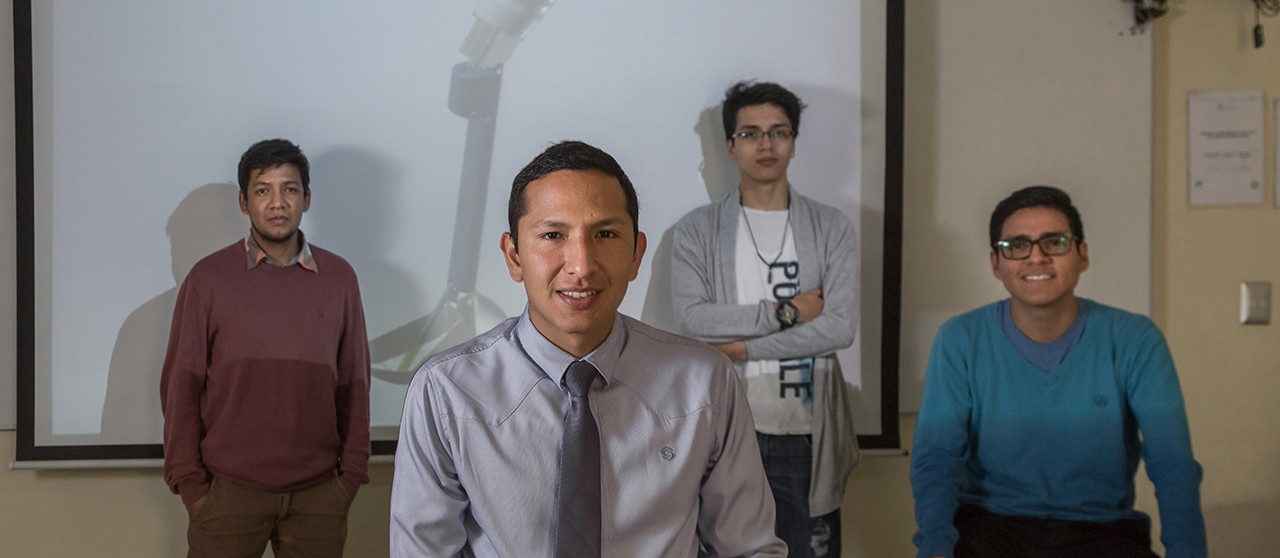

The idea came up in the class of Prototypes II. It was an idea you and Enzo Pizarro developed.

Yes. We were always thinking about what we could solve and how, not only for that class, but for ourselves as students, since the university gives us the opportunity to register patents.

How did your friendship start?

I met him when I changed my degree. We were the leaders of different teams. The first time we worked together, we did so well, we did not want to stop it.

Once you developed the idea, you noticed you needed more people from other specialisations.

Yes. We had planned to apply for the James McGuire Award by ourselves, but we had the chance to work with students from other specialties, which we thought it was great as they could contribute even more. Teamwork is highly helpful for development of projects, as there are more points of view. Teamwork could take our idea to the next level.

That is how you included two administrators, one mechatronic engineer, one nurse and one expert in rehabilitation.

We are 7. We all decided the group’s name: “Go for it, walk with me”.

This happened in less than a year.

That is right. Enzo and I participated in a competition before, but we did not win, because elaborating something great takes too much time, so we had to submit an incomplete project. This time, however, in spite of our doubts in working with new team members, we did it so well as we complemented each other.

“It would be selfish to have the knowledge to do things like this and not to do it.”

You won the national competition and some capital to execute your idea.

It was a beautiful experience. Instead of a prototype, we presented a mock-up and our proposal to the jury. It was very gratifying!

Is there a similar alternative in the world?

We found 3D printing proposals, but none of them is like ours, which uses injection.

What is your idea?

We want to create pieces for prosthesis that can be adjusted to the size of people. In the case of children, we want prostheses to accompany them as they grow. As for adults, we can renew prostheses by using their own old ones given that we work with recyclable material.

As you won the internal competition, you wanted to take it to the next level. You participated in the competition of the international network of universities, to which UPN belongs, but you did not win. Was that discouraging?

Not really. The fact that many people was interested in our proposal was satisfying enough. Now we want to do more with our idea. We want to make everything a reality in order for people to have access to prostheses.

That is your challenge.

Yes. That is why a group of teachers has joined our team. They will help us with technical things, design and paperwork to register the patent.

You have planned to have the first prototype ready by January 2019.

The first prototype that is functional, because we have made some that are mock-ups.

Why do you do this?

Because we feel highly motivated to accomplish things like this as students; because it has a social approach: it will help others. It would be selfish to have the knowledge to do things like this and not to do it. We know that many people can benefit from our work.

And you are not alone in this goal.

Around the world, there are many young people and adults looking for ways to solve the negative environmental impact caused by slow-degrading waste. For that reason, we want to add another use to material that is already trash, thereby avoiding they are left in a waste ground and creating a positive impact. Waste will always exist, but that does not stop us from doing our bit. We might not make a great change, but it is a contribution.

Turning 300 plastic bottles ―that are already trash― into a prosthesis that will allow a child to run is a great contribution, don’t you think?

Yes. We also want to make adults aware of the situation. Many believe they will not change, but we want to try. I am from Tarma, located in the Highlands, and I have seen how people live in villages; children are happy with so little. There is no much pollution. I would love it if more places had that harmony with nature! We should learn to value what nature gives us.

Great proposals usually come from central universities, not from Comas. That is one more point in your favour, isn’t it?

Yes. As students, our approach is based on environmental and social aspects, because that contributes to society. It would not be helpful to create a new model of a hoover which is highly efficient but it has many negative components, would it? That is not our approach, we focus on real problems to create alternatives that solve them.